Our instrument

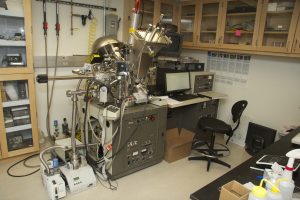

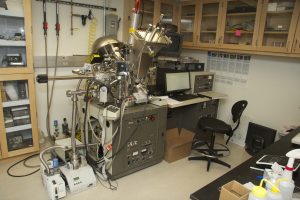

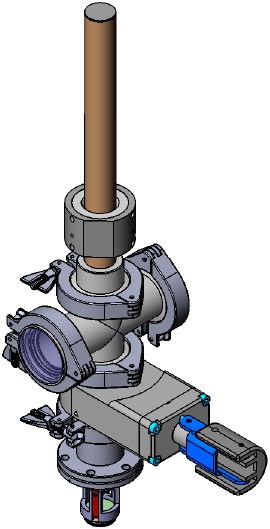

Our instrument is a Phi5600 multitechnique surface science analysis instrument. The instrument was provided and installed by

RBD instruments who refurbished the hardware, rebuilt the pumps, replaced the filaments, cleaned the analyzer, and notably,

interfaced the data acquisition system with a modern computer. For X-ray analyses, features include a twin (Al Kα/Mg Kα) x-ray anode, a monochromated aluminum Kα x-ray anode, and a 300 mm hemispherical energy analyzer with a 2-stage channeltron-amplified, 16-position electron detector. Sample preparation/cleaning includes an

in situ heating stage, an argon ion gun, and a low-energy charge neutralizer. We additionally utilize a

Prevac gas-excitation light source (typically He I and/or He II excitation) in ultraviolet photoelectron spectroscopy for valence band spectra determination. In the picture above, the mechanical pumps are also housed in the cabinet on the lefthand side to minimize vibrations and noise.

Instrument sensitivity, accuracy, and resolution are all within specifications for a Phi5600 system with an OmniFocus III lens. For excitation with the monochromatic Al Kα source, resolution is < 0.5 eV fwhm for Ag 3d5/2 at a 2.95 eV pass energy. Typical “publication quality” scans of a particular chemical region utilize a 23.5 eV pass energy to collect 10 scan averages (but up to 100 for sub-monolayer coverages of low-sensitivity elements) at a 25 meV step size and a 50 ms dwell time per point. The sampling spot size is < 1 mm2, and does not provide raster imaging capabilities.

Vacuum suitcase

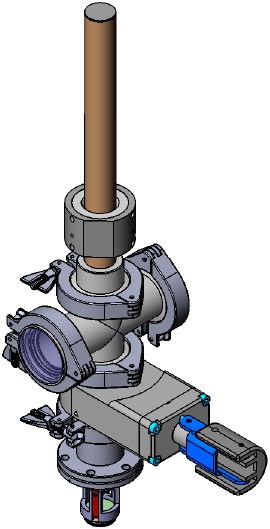

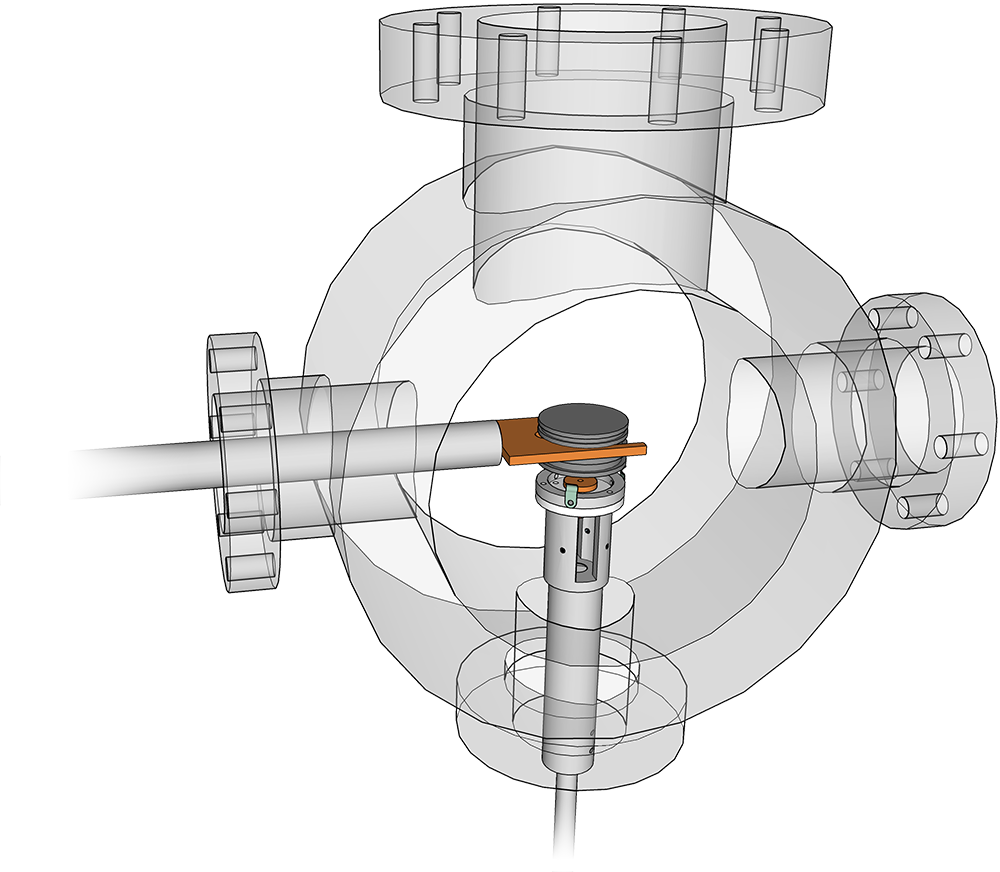

A device from

Transfer Engineering & Manufacturing enables direct sample transfer from a glovebox to the XPS with

no exposure to air. (This is particularly useful for analyses of lithium battery and other energy storage materials that might degrade even in the few minutes that it takes to remove a sample from the glove box then walk it over to the XPS and load it under an air ambient.) Termed the “vacuum suitcase”, this device adapts to 1″ Phi-style pucks for sample loading inside the glovebox and subsequently mounts on to the XPS load lock. The sample is sealed in the vacuum suitcase under the atmosphere from the glovebox that is nitrogen-or-argon based with a typical oxygen concentration under 1 ppm. The interface with the XPS is a KF40 flange (a 2.75″ Conflat is shown in the machine drawing), as its inner diameter clearance is sufficiently large for puck passage and KF can quickly mate to a matched, genderless flange.

Adams & Chittenden scientific glassblowers made an adapter to the XPS load lock based on a

glass KF40 flange so that we can visually align the transfer of the puck from the holder in the vacuum suitcase to the Phi sample transfer arm. This enables the analysis of air-sensitive compounds and thin films that would otherwise be destroyed by even short air exposures.

The suitcase has a side port that enables active pumping with a small, battery-operated pumping station for maximum oxygen-free sample transfer or for transport/storage over long distances/times. We do not presently use the suitcase in this way given that our glovebox is adjacent to the XPS for expeditious sample transfer.

Side chamber TPD

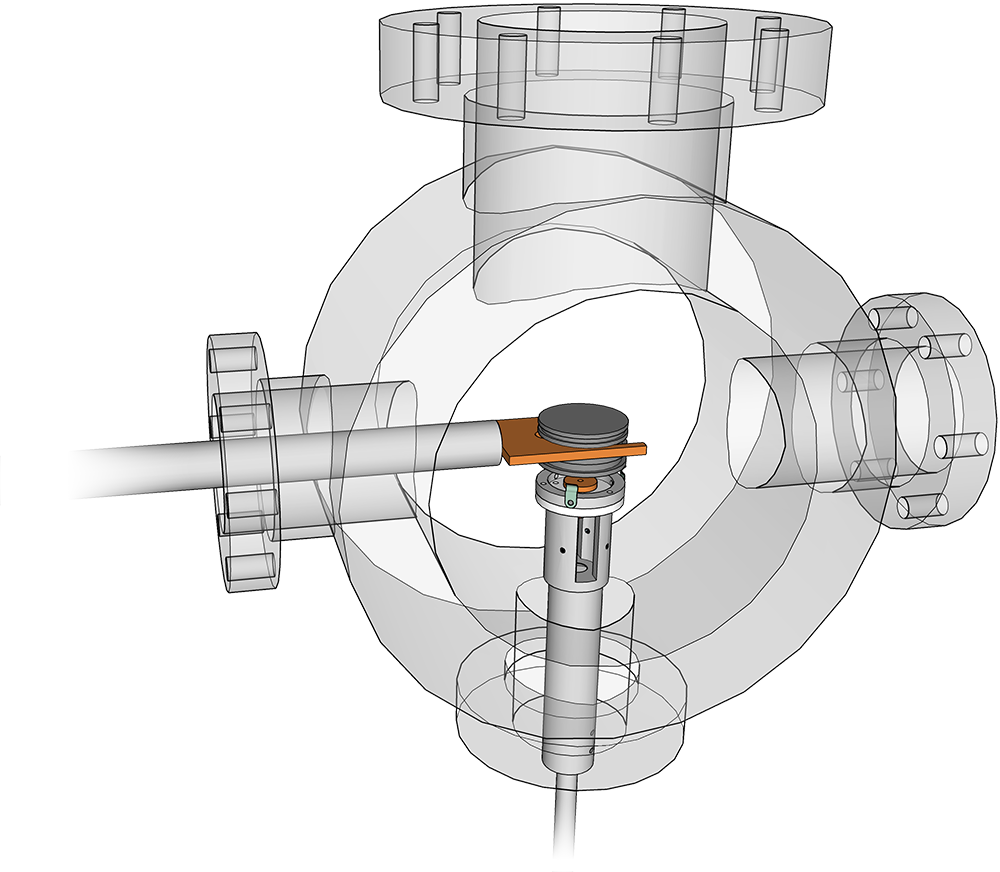

We have additionally outfitted a side chamber on the instrument with a

temperature programmed desorption experiment. The Phi5600 instrument as supplied came with Phi’s high-pressure reaction cell that was directly attached to the chamber and had a separate sample transfer arm for transferring Phi sample pucks between the XPS analysis chamber and this reaction cell. We subsequently modified the reaction cell by adding a sample stage on the lower port that receives a Phi-style puck and will raise the puck up to be adjacent to an electron impact mass spectrometer that is physically above the puck (not shown). Rather than using a traditional Phi puck,

HeatWave Labs fashioned a heating stage that physically resembles a Phi-style puck. We apply a current through the stage, and this heater puck gets hot! Since it has all of the grooves in the right place, the transfer arms can move this heater puck back and forth as if it were a “real” Phi puck. We measure temperature with a thermocouple that is near the mass spectrometer that is pressed in to the heater puck when it is raised to be adjacent to the mass spectrometer.

In summary

We are very grateful to all of the people and all of the businesses that enabled the kinds of experiments that we need to do to answer the kinds of questions that intrigue us. We are additionally grateful to Tom Partington in the Chemistry & Chemical Engineering instrument shop at WPI for his services in fabrication of TPD stage pieces and ongoing assistance.

Instructions for XPSing

Instructions to follow soon.

Instructions for UPSing

Instructions to follow soon.

Instructions for TPDing

No. Consult with Grimm for collaboration.

Research

Research

Energy

Energy

People

People